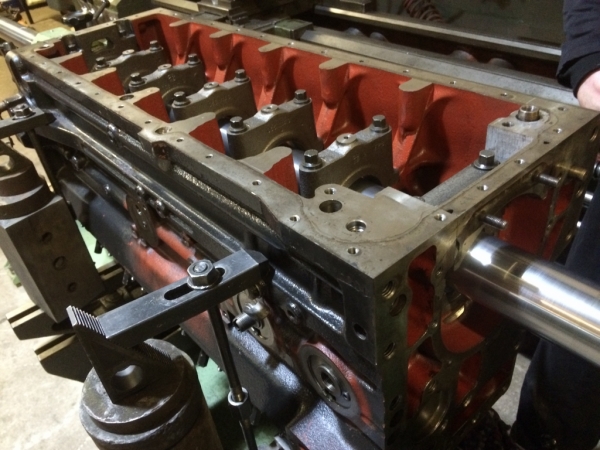

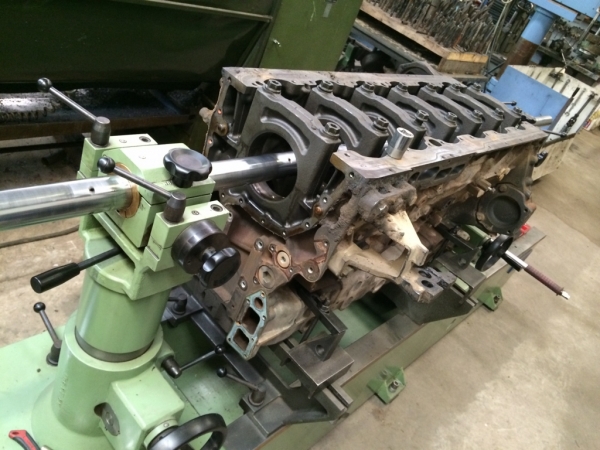

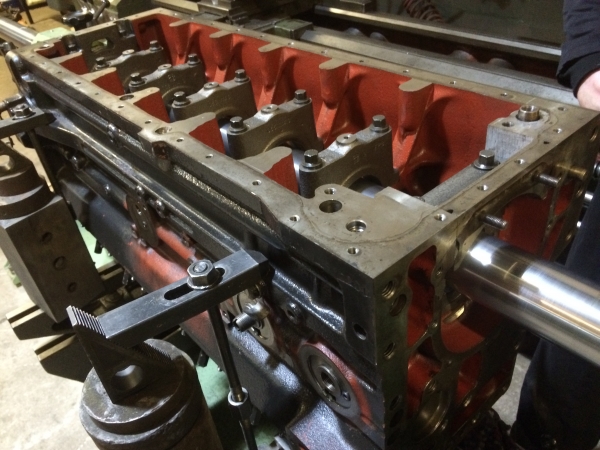

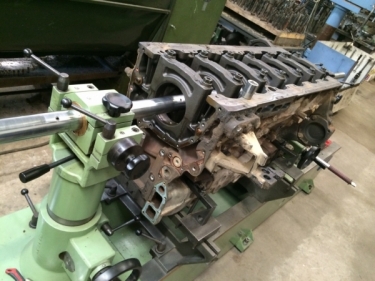

Cylinder Block Line Boring

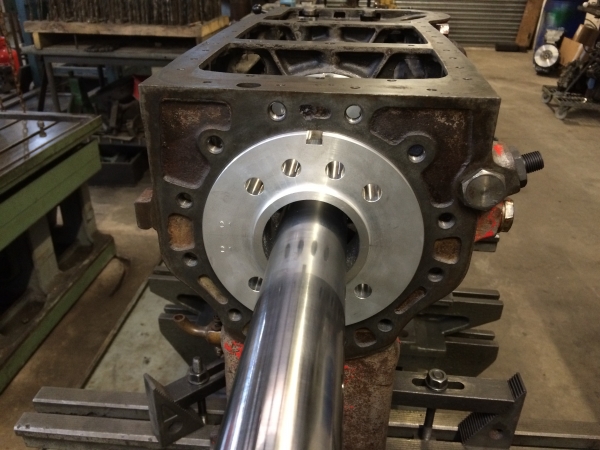

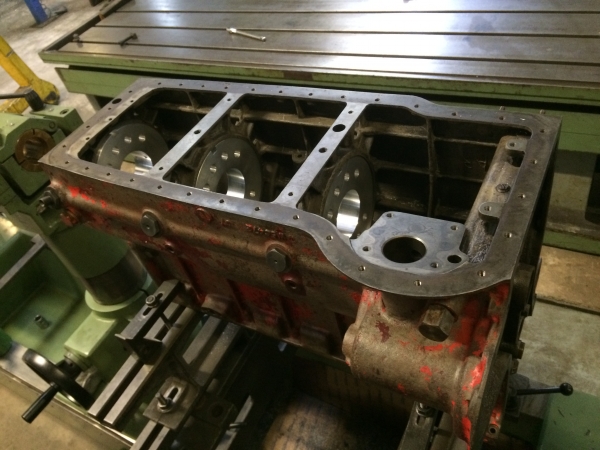

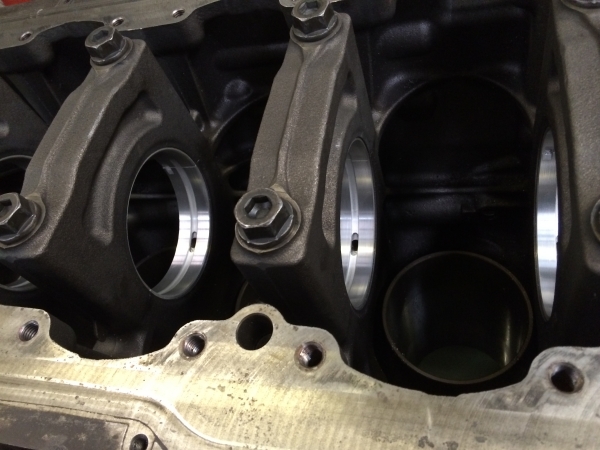

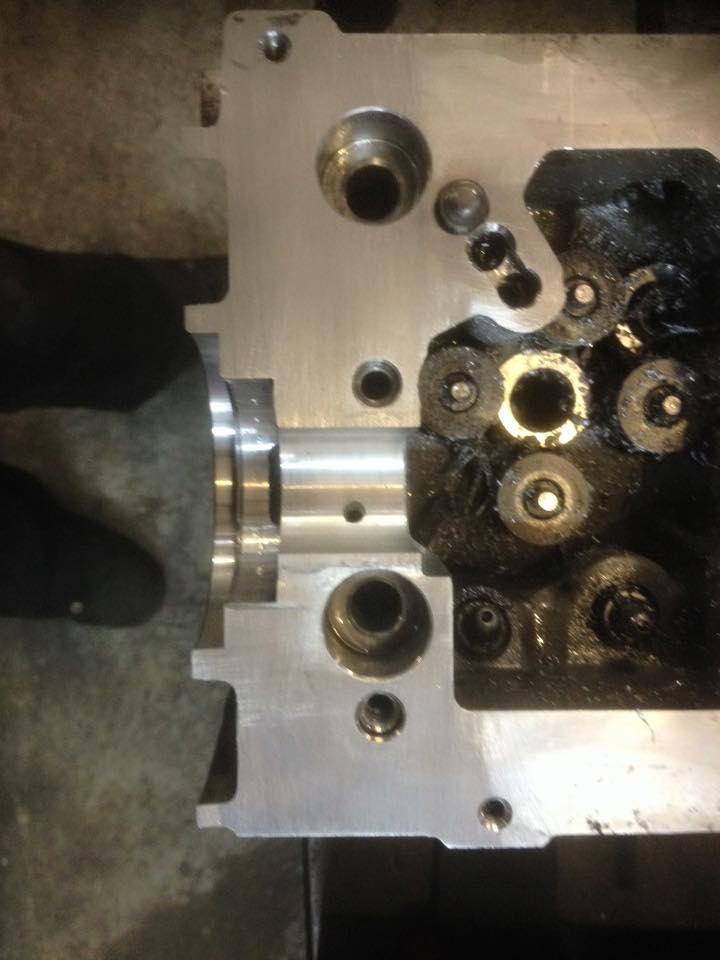

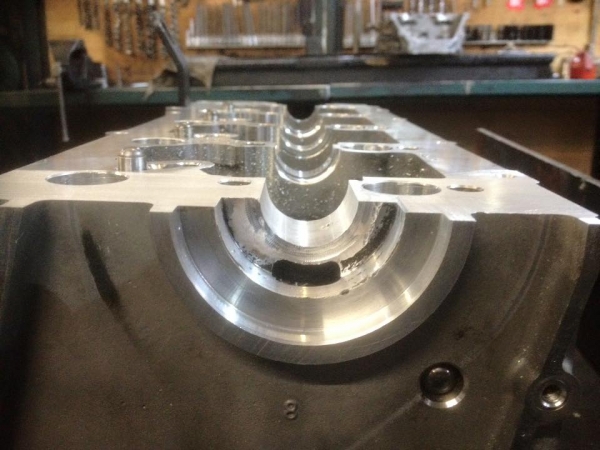

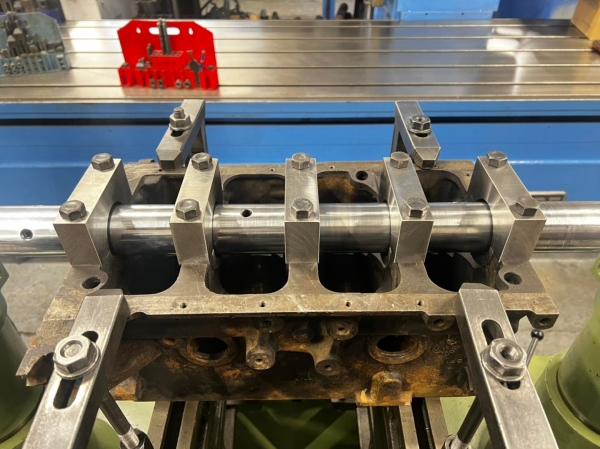

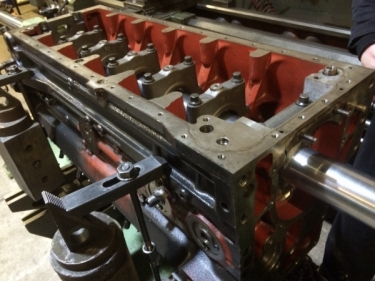

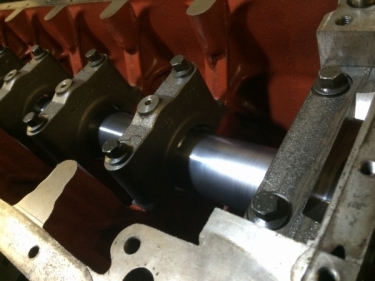

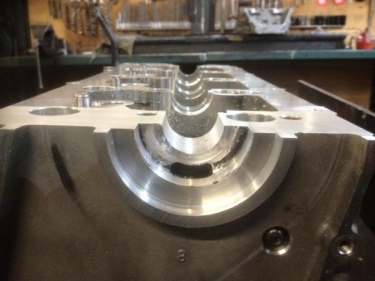

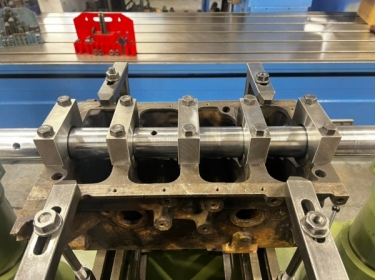

When referring to cylinder blocks, the term line boring is usually applied to the main bearing housings although it can equally be applied when referring to camshaft housings where the camshaft runs in the cylinder block itself. The line boring operation essentially restores both the sizing and alignment of these housings to ensure that the rotating components (camshaft or crankshaft), turn freely.

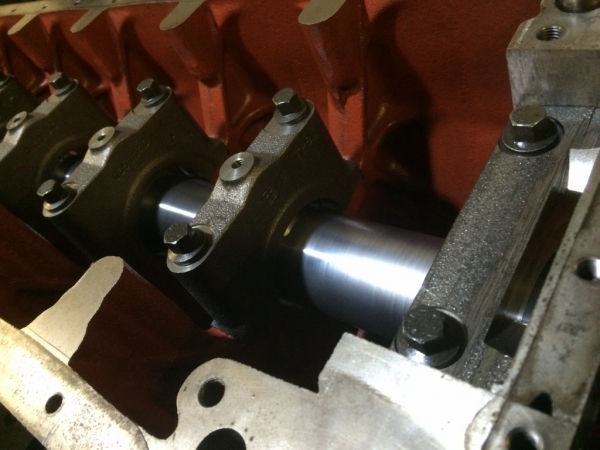

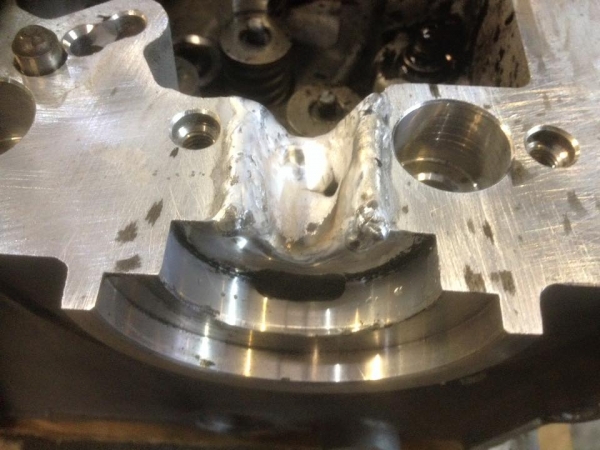

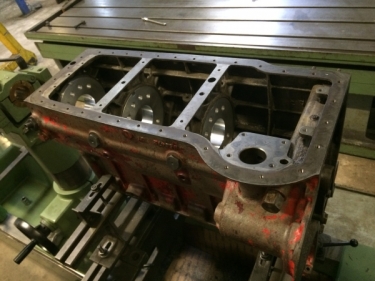

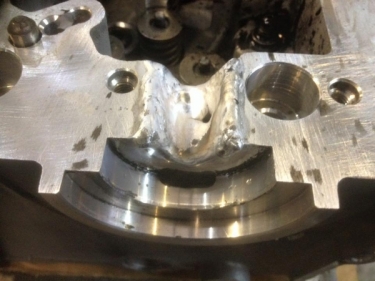

With cylinder blocks the most frequent reason to need a line bore is following a crankshaft failure. A badly worn crankshaft can “whip” within the main bearing housings which causes distortion within them. A seized crankshaft (through lack of oil or pressure) can cause the shell bearings to lock onto the crankshaft resulting in them being forcibly rotated within their housings causing both distortion and wear.

Equally, if a seizure occurs within the camshaft housing the cam bushes may be damaged or in extreme cases might rotate within the block itself. This can result in damage to the block which would require the housings to be bored oversize, removing the damage and correcting the alignment. Corresponding oversize bushes will be needed to fully repair the damage.

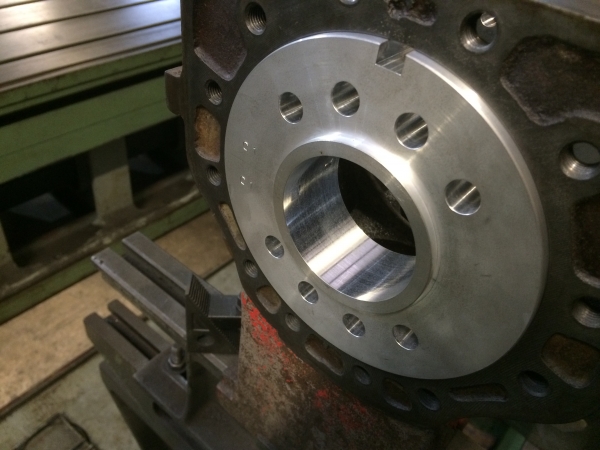

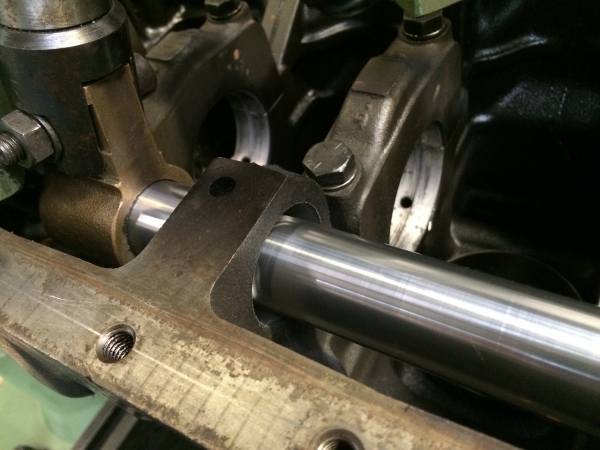

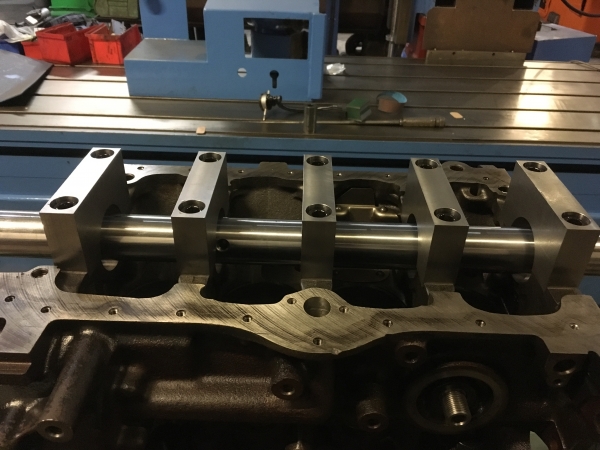

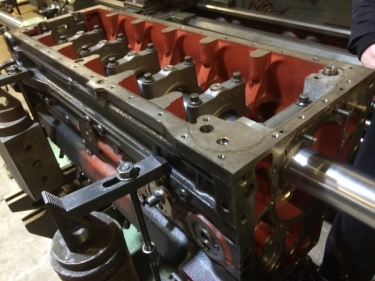

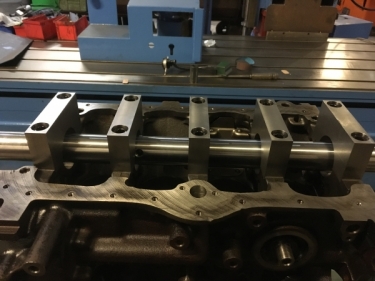

In high performance engines strength in the crankshaft area can be improved by fitting steel main bearing caps. These will be supplied in a semi-finished condition and line boring will be necessary to ensure perfect final alignment.

All or any of the above could mean that your casting needs to be line bored.

Some popular engines that we would work on with Main bearing housing problems would be -

- BMW N57 3.0 Diesel

- Landrover TDV6

- Vauxhall Insignia 2.0

- John Deere 4 cyl + 6 cyl

Also customers with high performance engines who decide to fit Billet main bearing caps then this is the process needed to bring your housings back to size.